Garage1217

Member

The start off, this post is basically a compilation of posts I made on another forum I no longer really attend documenting my progress on my new build to it's current state. Let the fun begin!

My goals for this system....

- High energy efficiency / at or less than .03 cents per hour running cost at .11 cents per KWH

- Large water volume

- Lots of DIY projects

So to kick this off, here is the basic equipment list that is going into this system. Tank is ordered as well as many other items and many I already own

- 225G lee-mar trimless eurobrace tank / front 3 sides in starphire / black silicone / diamon edges, ABS bottom - under glass / epoxied back wall / 1" returns - 1.5" drains / drains will be setup as a partial siphon with emergency dump... basically the works. Even the eurobrace is starphire *LOL*

- Building a custom stand for the tank

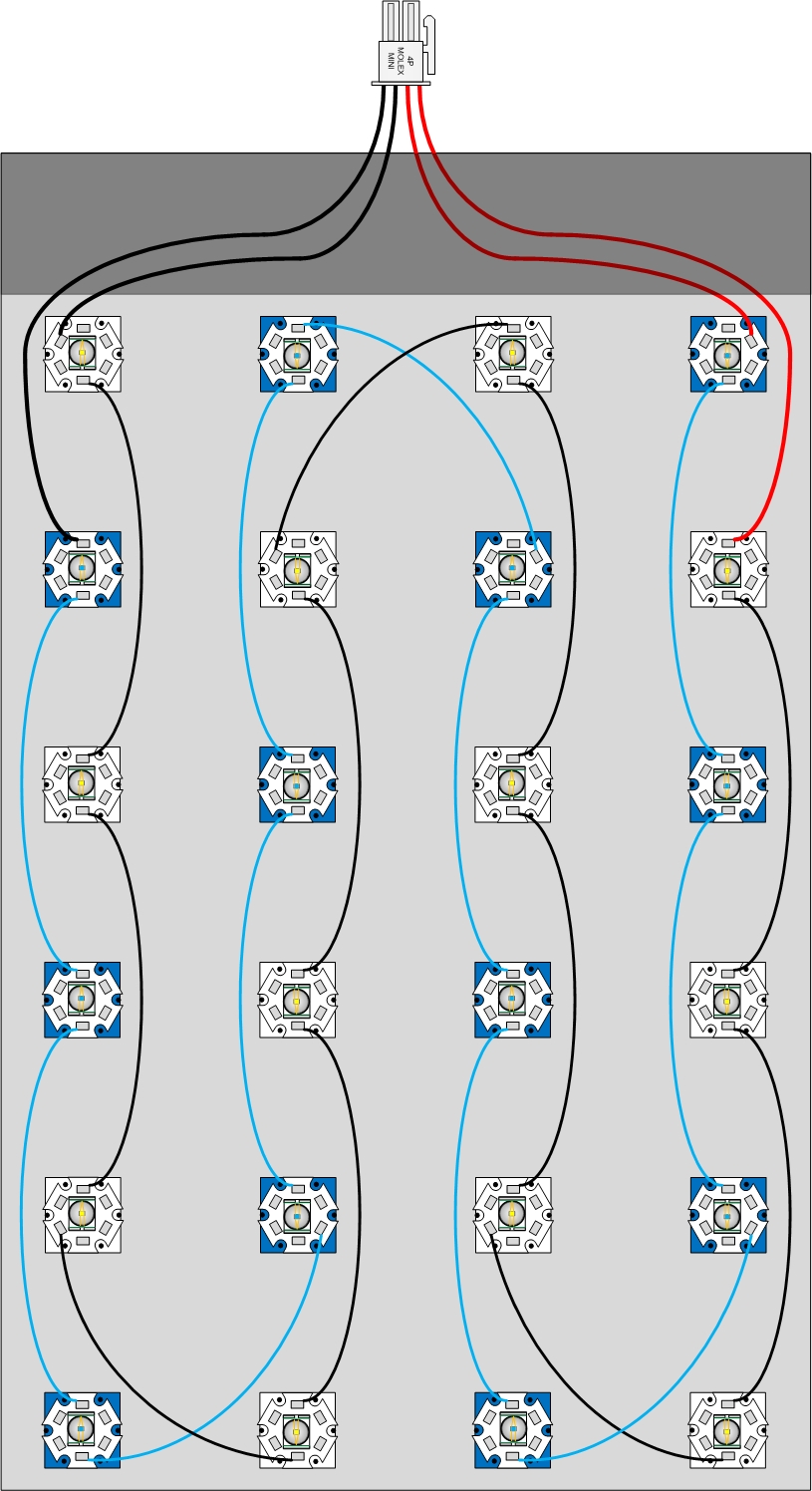

- 5 custom LED lights I am building will cover the tank / 120 leds total / 360w of cree XR-E wickedness w/80 degree optics "more details on this custom light build below" This will feature sunset and sunrise dimming ability!

- 4 koralia K4's "not koralia evos" modified with sureflow props blowing 1600+gph each.

- SRO-5000INT Super Reef Octopus skimmer with bubble blaster 5000 pump

- HY5000 Water blaster return pump

- 4 qty 150W Jager heaters

- Korralin 1502 ca reactor / will have to upgrade once I start really stocking this large of a tank

- Apex system controlling temp, ca reactor ph and lighting

- Spectrapure maxcap rodi for purification

I will have a LOT of pics coming soon as stuff is arriving slow, but first up! Some info on the lighting.

The display...

- will use 60 cool white cree XR-E Q5 - WE series leds

- 60 royal blue cree XR-E D3 series leds

- 80 degree optics

- 10 Meanwell ELN-60-48D

- Neptune systems aquacontroller with 0-10V outputs for sunrise - sunset dimming of the ELN-60-48D's

- Heatsinks are from heatsink USA and will be custom anodized black. They will be put together VERY nice & look professional.

- Airflow through the heatsinks will be provided by a SCYTHE|SY1212SL12H RT 120mm pc fan / 5 total. They are super thin and quiet / flow just the right about of air.

- Thermal control of the 5qty of led pads will be provided by an NZXT Sentry 5 channel fan controller / temp monitor

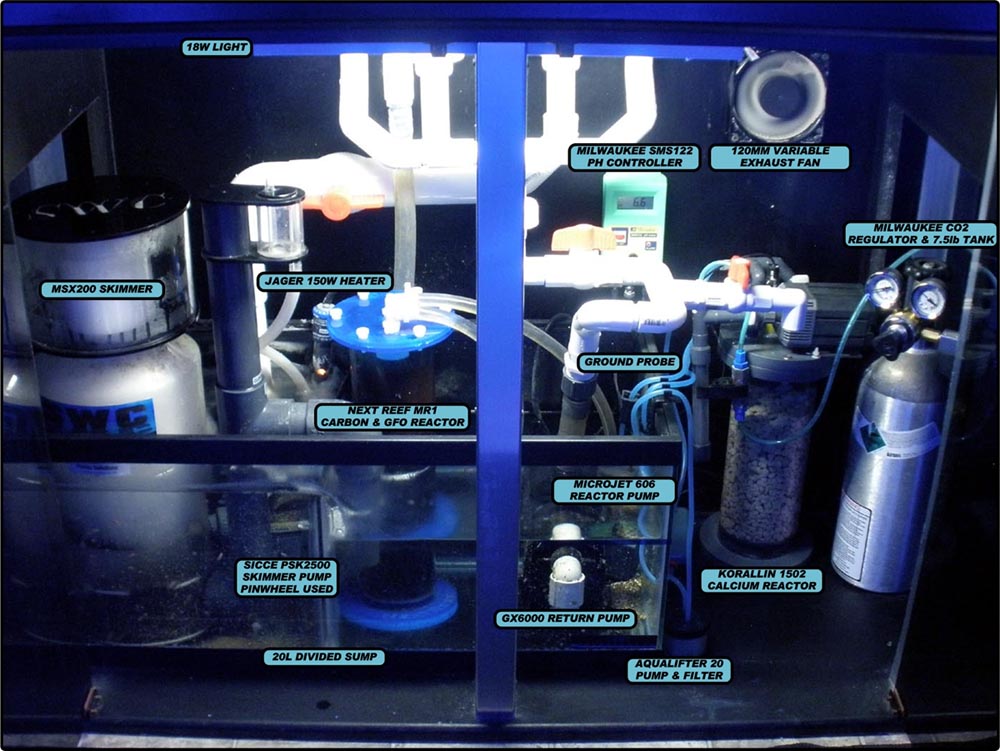

QT system

- 10G aqueon tank

- 20" t5ho light

- 8W current USA gamma UV

- Microjet 606 pump to feed gamma uv

- Koralia K1 for additional flow

- Aquaclear 20 for filtration

- Quick drain valve to evacuate system with plumbing to fill directly from the display tank

ATO

- 20H tank, painted black on 3 sides.

- Microjet 606 pump with anti siphon plumbing

- Custom built sensor assembly designed by me with no moving parts / no parts in the water. Tested for 90K cycles without a single hitch. May market this in the future as it is light-years beyond what is available for ATO today.

My goals for this system....

- High energy efficiency / at or less than .03 cents per hour running cost at .11 cents per KWH

- Large water volume

- Lots of DIY projects

So to kick this off, here is the basic equipment list that is going into this system. Tank is ordered as well as many other items and many I already own

- 225G lee-mar trimless eurobrace tank / front 3 sides in starphire / black silicone / diamon edges, ABS bottom - under glass / epoxied back wall / 1" returns - 1.5" drains / drains will be setup as a partial siphon with emergency dump... basically the works. Even the eurobrace is starphire *LOL*

- Building a custom stand for the tank

- 5 custom LED lights I am building will cover the tank / 120 leds total / 360w of cree XR-E wickedness w/80 degree optics "more details on this custom light build below" This will feature sunset and sunrise dimming ability!

- 4 koralia K4's "not koralia evos" modified with sureflow props blowing 1600+gph each.

- SRO-5000INT Super Reef Octopus skimmer with bubble blaster 5000 pump

- HY5000 Water blaster return pump

- 4 qty 150W Jager heaters

- Korralin 1502 ca reactor / will have to upgrade once I start really stocking this large of a tank

- Apex system controlling temp, ca reactor ph and lighting

- Spectrapure maxcap rodi for purification

I will have a LOT of pics coming soon as stuff is arriving slow, but first up! Some info on the lighting.

The display...

- will use 60 cool white cree XR-E Q5 - WE series leds

- 60 royal blue cree XR-E D3 series leds

- 80 degree optics

- 10 Meanwell ELN-60-48D

- Neptune systems aquacontroller with 0-10V outputs for sunrise - sunset dimming of the ELN-60-48D's

- Heatsinks are from heatsink USA and will be custom anodized black. They will be put together VERY nice & look professional.

- Airflow through the heatsinks will be provided by a SCYTHE|SY1212SL12H RT 120mm pc fan / 5 total. They are super thin and quiet / flow just the right about of air.

- Thermal control of the 5qty of led pads will be provided by an NZXT Sentry 5 channel fan controller / temp monitor

QT system

- 10G aqueon tank

- 20" t5ho light

- 8W current USA gamma UV

- Microjet 606 pump to feed gamma uv

- Koralia K1 for additional flow

- Aquaclear 20 for filtration

- Quick drain valve to evacuate system with plumbing to fill directly from the display tank

ATO

- 20H tank, painted black on 3 sides.

- Microjet 606 pump with anti siphon plumbing

- Custom built sensor assembly designed by me with no moving parts / no parts in the water. Tested for 90K cycles without a single hitch. May market this in the future as it is light-years beyond what is available for ATO today.