Rhodes19

Active Member

Well, I have been on RS for a while now and I have some pictures of my 180 build I can share. This is going to be a slow build because of money, time, and knowledge/experience (not always in that order). It started when a friend of mine started to live vicariously through me and got me interested in reefs (he had to take his down) so I started my 29g reef. That went well so I converted my BC 14 at my office from WF to reef and that went well. Next think I know, my friend is telling me about a 125 at a LFS. My wife caught wind of this and my friend’s response was that I would be getting it for her! As he explained it, a bigger tank would have the equipment stored underneath it and would be quiet (my 29 sits near the couch and TV and the HOB skimmer interferes with her listening pleasure). So next thing I knew, I had permission to get a big tank!!!  I found my 180 in Jan/Feb time frame and brought it home and have been trying to make a stand for it and collect the needed equipment. Here is where I am at the moment.

I found my 180 in Jan/Feb time frame and brought it home and have been trying to make a stand for it and collect the needed equipment. Here is where I am at the moment.

Home and in the garage

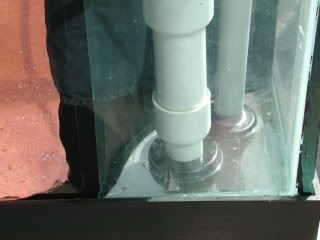

Came with Durso and returns

Next I started building my stand. I used 2x8s for the top and bottom frames and 2x4s for the legs. After I finished the framing itself, I realized that I made the opening in the front too small to squeeze in my 55 for a sump/fuge. SO, now I have a new work bench!!

I found my 180 in Jan/Feb time frame and brought it home and have been trying to make a stand for it and collect the needed equipment. Here is where I am at the moment.

I found my 180 in Jan/Feb time frame and brought it home and have been trying to make a stand for it and collect the needed equipment. Here is where I am at the moment.Home and in the garage

Came with Durso and returns

Next I started building my stand. I used 2x8s for the top and bottom frames and 2x4s for the legs. After I finished the framing itself, I realized that I made the opening in the front too small to squeeze in my 55 for a sump/fuge. SO, now I have a new work bench!!

The funny part is now he is thinking about getting back into reefing and is not sure how to explain it to his wife!! :LOL: He even almost picked up a used tank the other day. I can't wait until he does. My wife even offered to help him spend HIS money!

The funny part is now he is thinking about getting back into reefing and is not sure how to explain it to his wife!! :LOL: He even almost picked up a used tank the other day. I can't wait until he does. My wife even offered to help him spend HIS money!