You got it. I will clean it up later and take some pictures for you. thanks buddy! I will post them tonight. I am also thinking if i do fix it i will make a manifold for it like Weatherson did. this could help keep that joint out of the water and increase the contact. Heres a link to what he did. It's near the middle of the page. Tank of the Month - April 2008 - Reefkeeping.com

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Frankie's 120gal. glass experiment

- Thread starter Frankie

- Start date

- Status

- Not open for further replies.

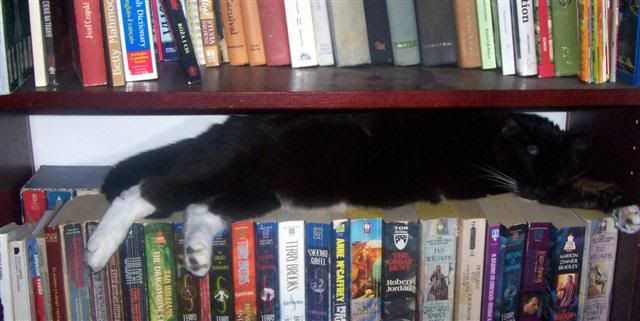

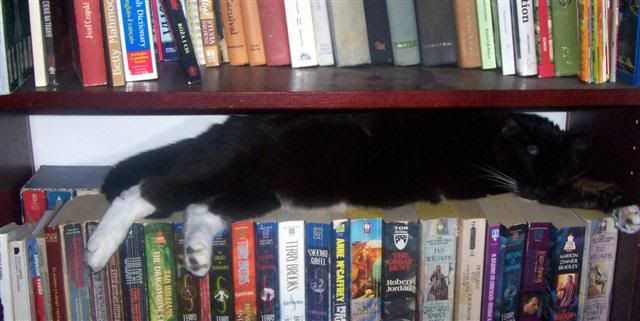

Ok, here is the first picture. My cat hard at work.

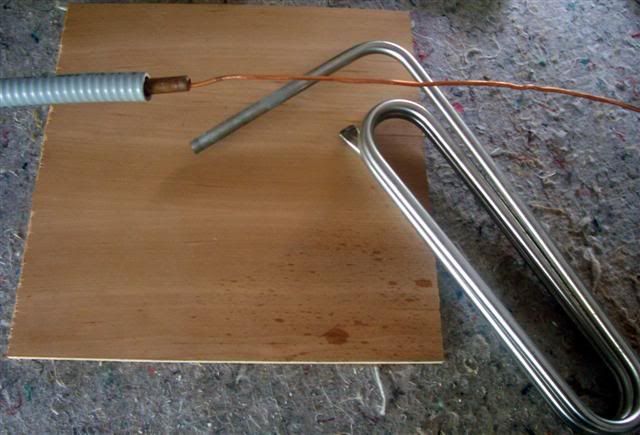

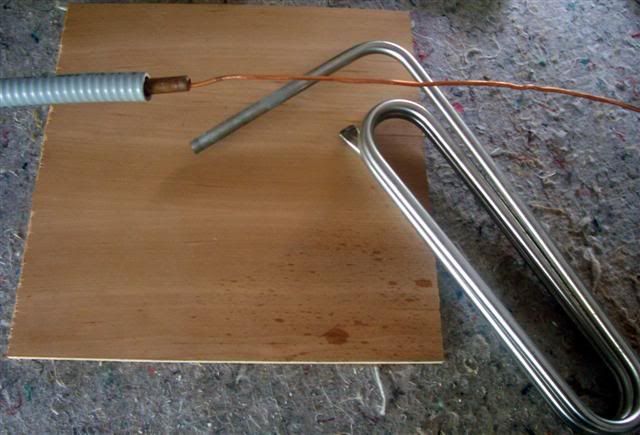

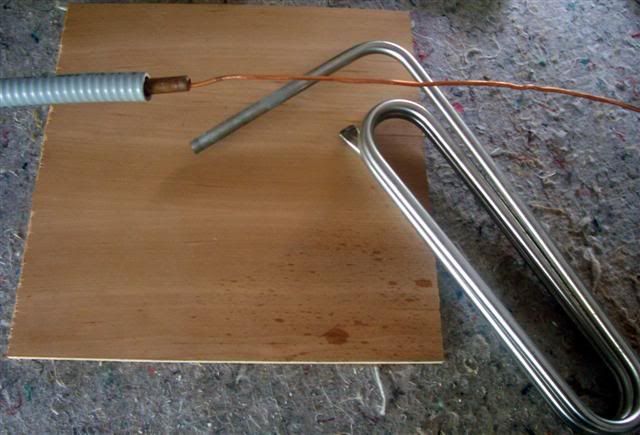

But this is what i have to work with Sas. What has to happen is that long thin compression line needs to be shoved down inside the titanium coil an then the titanium coil needs to be connected to the copper one. Really simple

But this is what i have to work with Sas. What has to happen is that long thin compression line needs to be shoved down inside the titanium coil an then the titanium coil needs to be connected to the copper one. Really simple

Craig Manoukian

Well-Known Member

Great pics and yesthe KISS principal really works!

Ok, here is the first picture. My cat hard at work.

But this is what i have to work with Sas. What has to happen is that long thin compression line needs to be shoved down inside the titanium coil an then the titanium coil needs to be connected to the copper one. Really simple

Frankie, trying to solder it may destroy the inner line, I suggest a double ended compression fitting and some shrink wrap or a few coats of epoxy.

Last edited:

LOL! Thats what i tried before and it leaked. I will try again then. I spent an hour chiseling the epoxy off of the compression fitting i had on it today!. I think the problem i had was i jumped the gun and filled it with freon to fast and a pin prick leak in the compression fitting pushed out the epoxy. Any recommendations on what epoxy to use?

Thanks for the help Sas. I feel better now knowing i was on the right path before. Just not a clean job.

Thanks for the help Sas. I feel better now knowing i was on the right path before. Just not a clean job.

JWarren

Active Member

Check pages 787 & 3531 here McMaster-Carr

althea2you

Active Member

awww! look how cozy the cat looks... as far as your recent topic.. its like reading a foreign language to me.. NO clue what your talking about! but i hope it goes better the second time around!

- Status

- Not open for further replies.