stilgore

Member

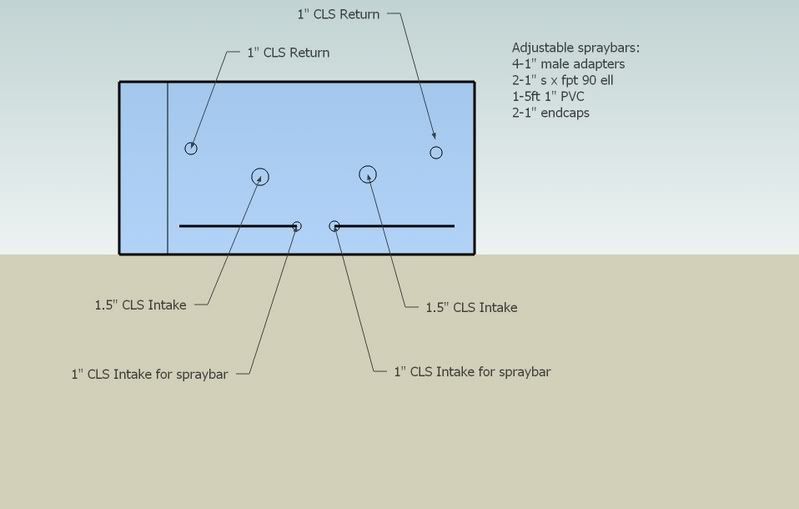

I will be starting the plumbing on my 300 this weekend (hopefully) as this is the first time I have undertaken such a large plumbing job I have a few questions.

Here is the first:

I want to maximized the flow through the tank. It is 8 feet long and I want to ensure I do not have any dead spots. Would I be ok if I plumbed two outputs under the water?

If I decided to do this I would either put a T in the return and drill the overflow or I would bring the PVC up over the overflow.

I ask if it would be ok because I have no clue about flow and the dynamics of water. I want to be sure there will be no damage to my pump if I have to shut the system off.

Thanks,

Stil

Here is the first:

I want to maximized the flow through the tank. It is 8 feet long and I want to ensure I do not have any dead spots. Would I be ok if I plumbed two outputs under the water?

If I decided to do this I would either put a T in the return and drill the overflow or I would bring the PVC up over the overflow.

I ask if it would be ok because I have no clue about flow and the dynamics of water. I want to be sure there will be no damage to my pump if I have to shut the system off.

Thanks,

Stil