cbui2

Member

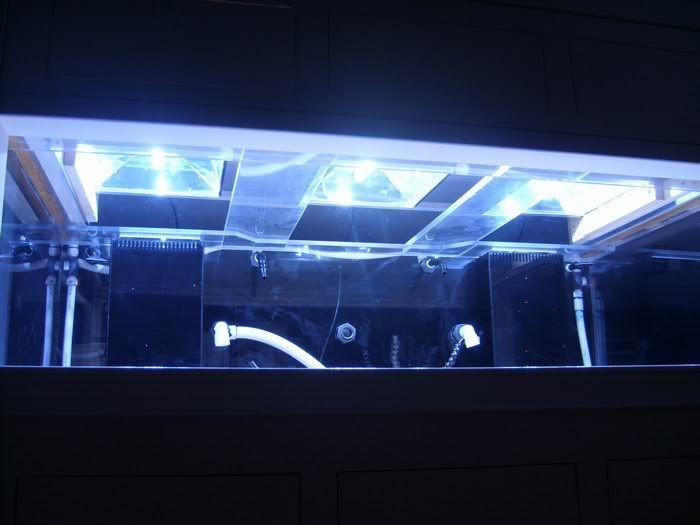

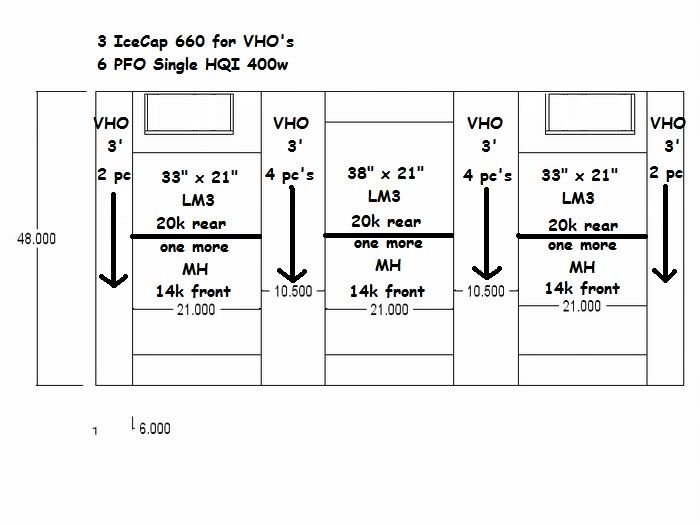

5-14: ok finally finished with cabinet and I am happy how this turn out, just plain and simply exactly how I liked it. I figure if all the trim molding was painted white then I can tell where the tank begin and ends. since i have blended the cabinet in with the entire wall. it has such a better view from all different angles. i will be working on lighting this week then chiller will be mounted and finished the rest of plumbing. 1 step closer on getting rocks & water in.