I over thought the process, than reduced it to the easiest method. I enjoy the fruits of my labor. As far as I am concerned, The hard work is done. All that is left is the plumbing and the sump layout, which is only based on my heater....which is HUGE and will be simple. Ill explain my thoughts as best I can.

This is the "test fit" of a unmolested corner box. I test fit it to verify that I could get both my durso and the bulkhead out. 2 thumbs up.

I then layed out teeth, and attempted to try my luck with a grinder and a 1/8" wheel. It works much better on carbon steel. These things were tossed.

@StirCrayzy

@StirCrayzy

Your advice about the drill bit had me crunching numbers, and I want the maximum flow rate. A "no-teeth" setup is the only way to take the math out of size of holes, and relative elevation of where they would actually work. My pump runs from 260-450 gph. I figure I will lose at least 25% due to head loss from fittings and height.

I had to figure out the best way to glue these in without any glue "tank-side"

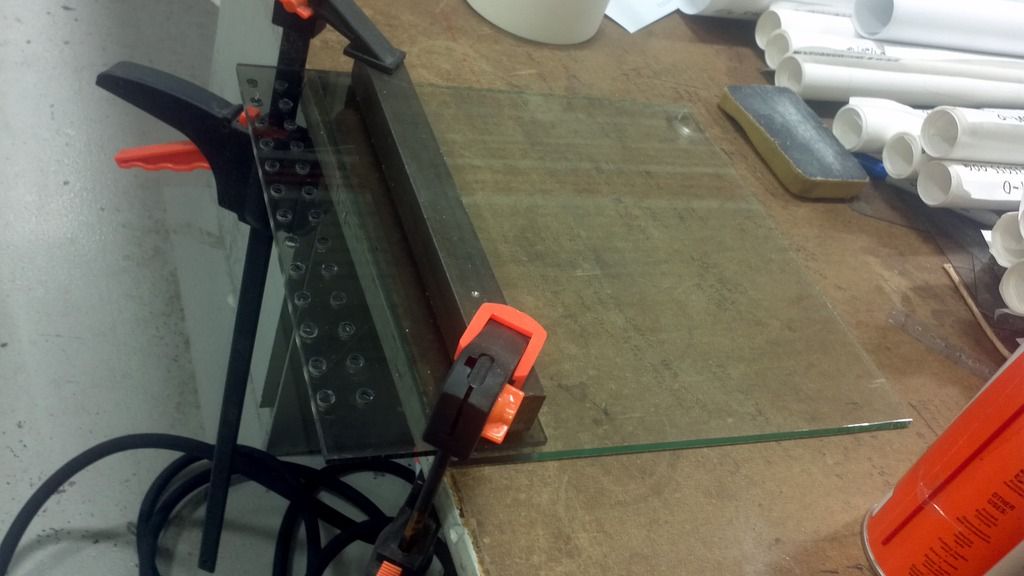

Step1: Secure and glue triangle. Also, the other piece is my layout for my 2 reinforcement squares for the backside of the tank. They are visible in a few photos.

Step2: I beveled the bottom edge of the "face" of the overflow. Then I secured it with tape. Then I hinged it open from the top. I caulked the corner piece from side to side, than folded it back down and waited for that glue to dry. I had all exterior faces masked with more blue tape than is on most rolls.

Step3: Mask off area on the sides of the "face" piece. Then cram glue into the V shape from where the corner tangent hits the tank, and I flushed it up with the angle of the face.

Tommorrow I will mask off most of the tank. I want to hit the overflow boxes with some Krylon Fusion paint which is safe if given more than enough time to cure (7+ days). I have the time to wait for the silicone. Also, I will be painting the background Black on the outside...And the piece of eggcrate on the back wall...That is my "anti-strike" background. I figure if it is black as the background, it will blend in.

Thanks

@BigAl07 for your prior thoughts on Krylon Fusion:

http://www.reefsanctuary.com/forum/index.php?threads/reef-safe-paint.63487/#post-869369

That looks great...but what about my livestock going over the Niagara falls? Also a cameo of my "reinforcement" plate on the back of the tank.

This is the most dead simple way I could think to engineer an overflow box without teeth, but with livestock loss prevention. That piece is tight in both boxes, but is not glued in any way. I don't think Id even have to.

I am projecting water this coming weekend. My live rock stunk from the shrimp slightly for 2 days. That "bio-spira" product must have actually done some good, because there is no reason other than that why my garage does not smell like low tide at the bay in August.