KimPossible

Well-Known Member

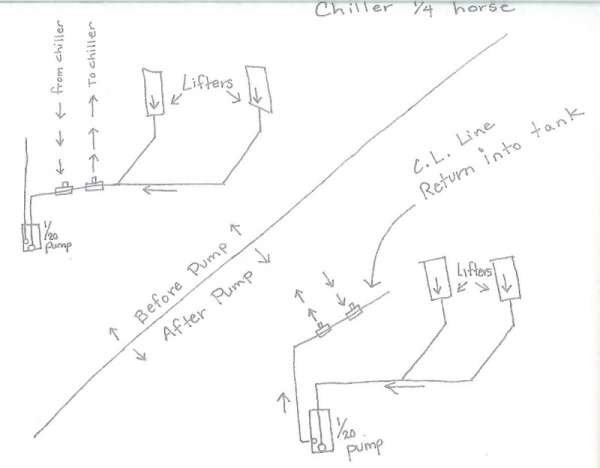

I'm plumbing the closed loop of my new 120.

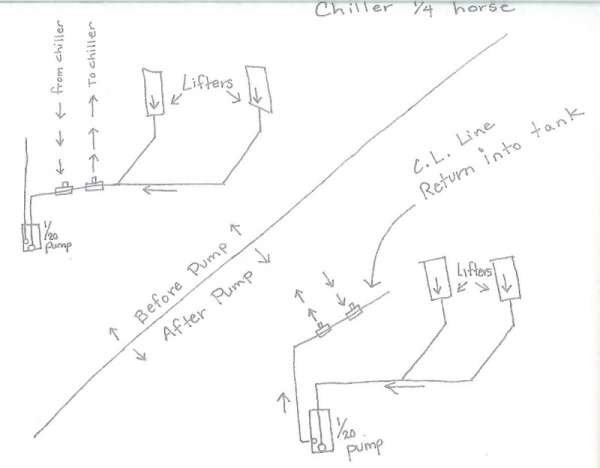

I decided to run the chiller off of my CL. I have dry plumbed it as shown in the "before pump" drawing seen below. My question is, have I created a vacuum? I don't want water just sitting in the chiller.

I have used 1" pipe throughout the closed loop system EXCEPT for the T's which reduce down to 3/4" for the chiller lines.

I have drawn up an alternative scenario. Would you take a look at what I have done and the alternative and give me some input? I am plumbing the tank myself and am nervous whether or not I have done this correctly.

TIA

I decided to run the chiller off of my CL. I have dry plumbed it as shown in the "before pump" drawing seen below. My question is, have I created a vacuum? I don't want water just sitting in the chiller.

I have used 1" pipe throughout the closed loop system EXCEPT for the T's which reduce down to 3/4" for the chiller lines.

I have drawn up an alternative scenario. Would you take a look at what I have done and the alternative and give me some input? I am plumbing the tank myself and am nervous whether or not I have done this correctly.

TIA