Actually the loop I speak of would put a constant pressure on the pumps return, and would not have an excess flowing to the sump. It would basically be a rectangle fed from both ends, with the outlets tothe individual tanks spaced out as needed. The assumption or principle is that by having a full boxed in loop and by feeding from both ends the pressure, and thereby the flow, will be equal at all exit points. It of course will not be perfect but good enough to avoid the need for balancing valves. a liitle extra pipe and a few fittings is a lot cheaper than a lot of valves. Ball valves in a partially closed position re very restrictice (thet are designed for an all off or all on usage) and gate valves are very expensive.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Grow out system?

- Thread starter Woodstock

- Start date

Thanks again for all the great comments.

This is the weekend to get the grow out together and plumbed!!

Any volunteers??

I have waiting for me at home;

That will be a total of at least 300 gallons

...hummm... I guess I'll start buying my salt 2 buckets at a time now...

Pics to come.. I promise!

Fun, Fun!!!

This is the weekend to get the grow out together and plumbed!!

Any volunteers??

I have waiting for me at home;

- a newly made wooden, 2-shelf rack,

- 10x 20 gallon (drilled w/overflow),

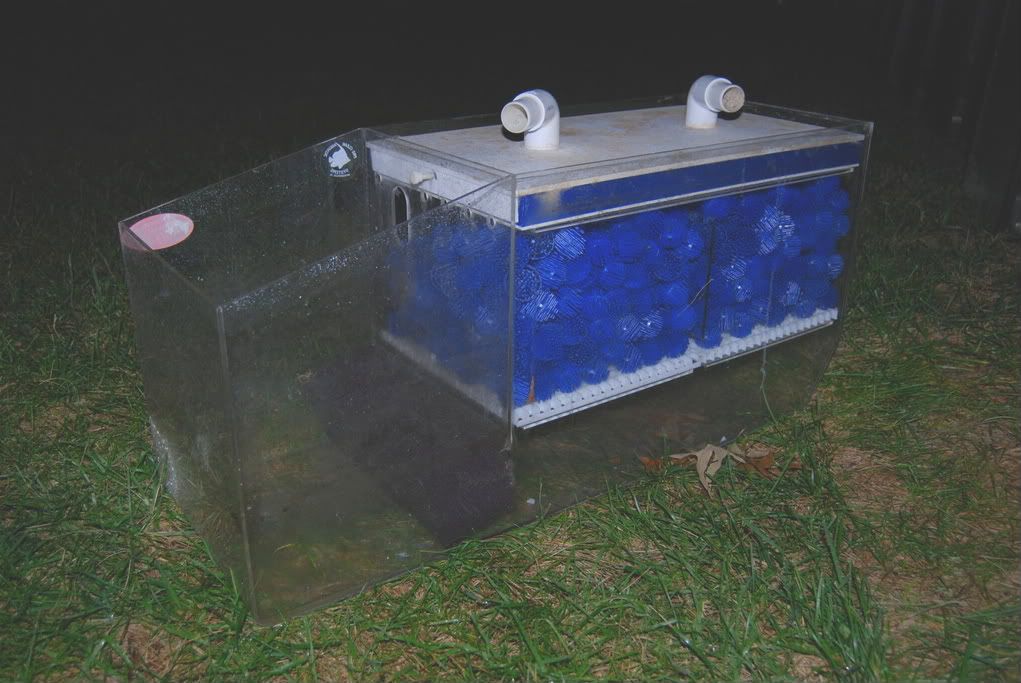

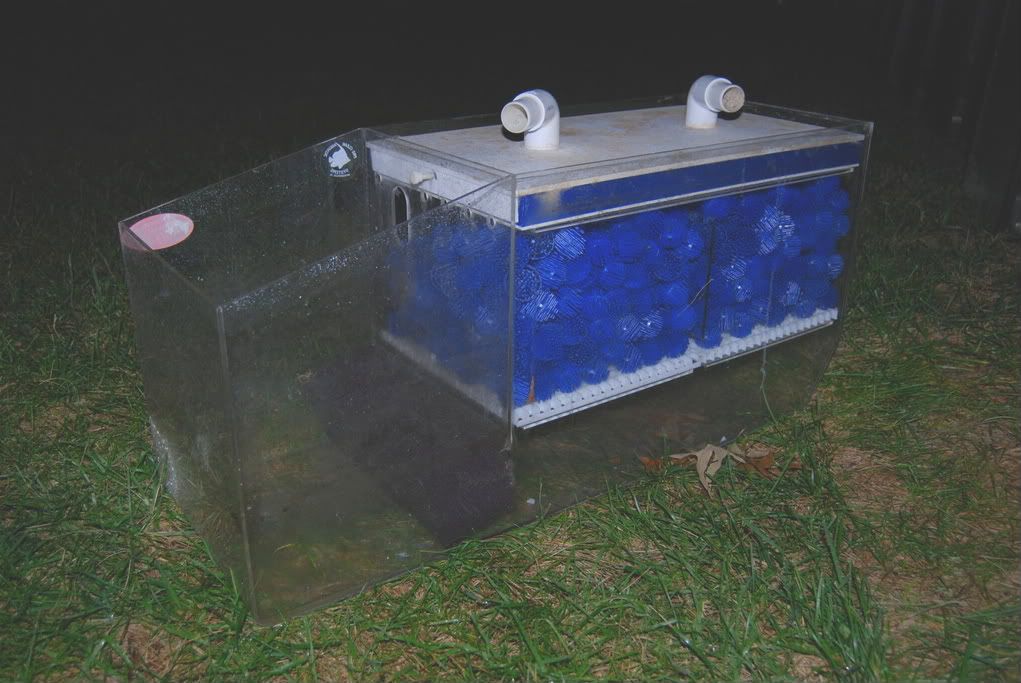

- and a large bioball acrylic sump.

That will be a total of at least 300 gallons

...hummm... I guess I'll start buying my salt 2 buckets at a time now...

Pics to come.. I promise!

Fun, Fun!!!

I will think positive thoughts at NC this weekend Doni. Remember, you can make a neater job of it with clear pvc primer instead of the purple. Always use fresh primer and glue if it's been sitting for a while. It does go bad over time. Nikki from RF found that out the hard way a few years ago.

If you run into any snags my cell is always on. Have fun!

If you run into any snags my cell is always on. Have fun!

Wow. It is taking much longer than originally thought to complete this project. I have the drain plumbing about 75% complete and have only purchased most of the parts for the return plumbing.

The local feed store only had one Rubbermaid 100 gal stock tank and it was damaged. I picked up a 50 gal and took it home but it was just too small so I returned it. They should receive an order of new 100 gal on Wednesday.

I will have two sets of drains - the top 5 tanks and the bottom 5 tanks will be on separate drain pipes - all w/1" bulkheads draining into a 2" PVC pipe which goes into a wet/dry bioball sump.

The wet/dry will be drilled for a 1" bulkhead and will be gravity fed into the 100 gallon Rubbermaid container. The 100 gal Rubbermaid will have a 4" sand bed and will be filled with chaetomorpha.

It will be drilled for a 1" bulkhead and an Iwaki 55RTL (japanese motor) external pump will push the water back up into the 10 tanks.

I will reduce the 1" pipe to a 1/2" just before going into each tank (6" or so) and will have a ball valve there to adjust the flow.

Although I have worked on this project for many hours, it seems the only thing I have managed to complete is setting the tanks on the stand. LOL

Ohhh... I did start cycling the bioballs last week! woot!

I placed an aqua-clear powerhead into the last chamber and added a vinyl hose to direct the water back into the drip tray. I added lots of ammonia and several 'colonized' sponges.

Here is a pic of the 10 tanks waiting patiently beside the garage

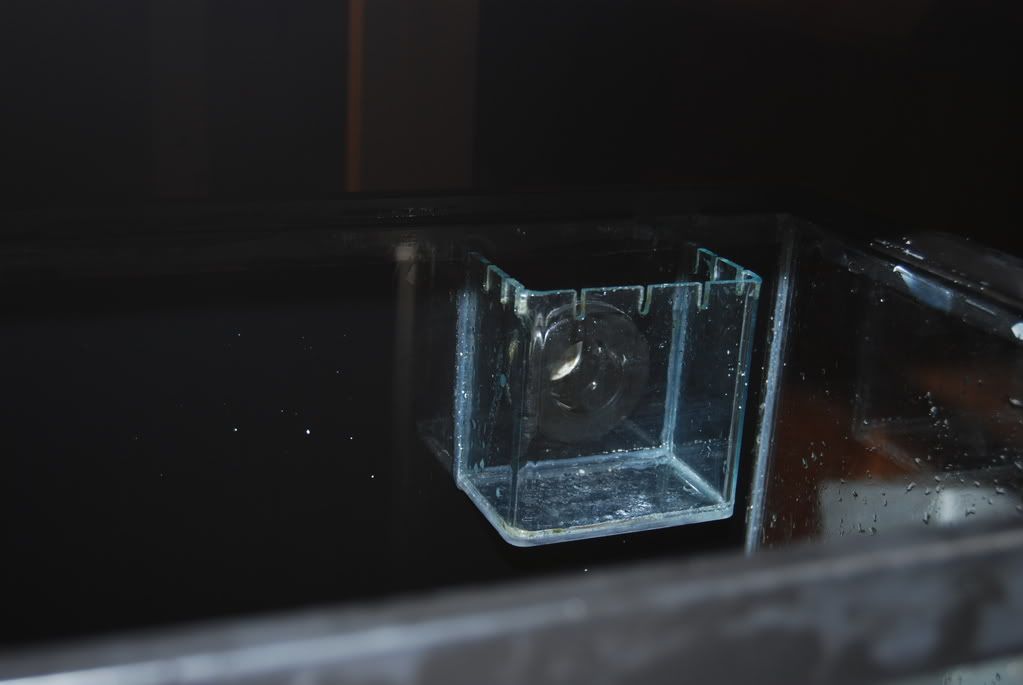

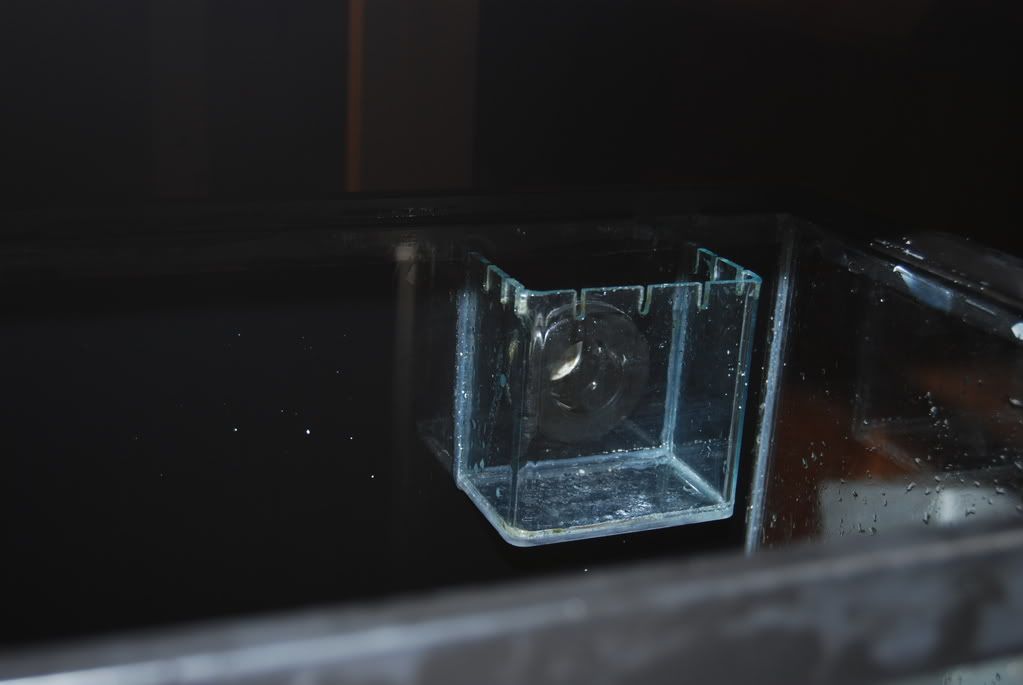

Here is a photo of the small overflows in each tank. I will need to put window screening around it for the small babies.

Here is my "office" The stand with only one 20 gal tank on it...

The stand with only one 20 gal tank on it...

The local feed store only had one Rubbermaid 100 gal stock tank and it was damaged. I picked up a 50 gal and took it home but it was just too small so I returned it. They should receive an order of new 100 gal on Wednesday.

I will have two sets of drains - the top 5 tanks and the bottom 5 tanks will be on separate drain pipes - all w/1" bulkheads draining into a 2" PVC pipe which goes into a wet/dry bioball sump.

The wet/dry will be drilled for a 1" bulkhead and will be gravity fed into the 100 gallon Rubbermaid container. The 100 gal Rubbermaid will have a 4" sand bed and will be filled with chaetomorpha.

It will be drilled for a 1" bulkhead and an Iwaki 55RTL (japanese motor) external pump will push the water back up into the 10 tanks.

I will reduce the 1" pipe to a 1/2" just before going into each tank (6" or so) and will have a ball valve there to adjust the flow.

Although I have worked on this project for many hours, it seems the only thing I have managed to complete is setting the tanks on the stand. LOL

Ohhh... I did start cycling the bioballs last week! woot!

I placed an aqua-clear powerhead into the last chamber and added a vinyl hose to direct the water back into the drip tray. I added lots of ammonia and several 'colonized' sponges.

Here is a pic of the 10 tanks waiting patiently beside the garage

Here is a photo of the small overflows in each tank. I will need to put window screening around it for the small babies.

Here is my "office"

:lurk:

So is it coming together? I can't help ya this weekend, but if it isn't up by next weekend let me know. I'll make a trip to visit the grandkids

LOL~ It is s l o w l y coming together. I should begin to make some fast progress this week but feel free to visit anytime!

looks good woody!!!

how come you are using bioballs? i thought they arent the best for tanks?

Remember this is a fish-only system... and will be an EXTREMELY heavily stocked system. The first and foremost issue is to reduce the ammonia and nitrItes by creating a biological filter. This is best accomplished by highly oxygenated surface area covered in bacteria -- bioballs are perfect for that. VERY fast and efficient reduction of the toxic ammonia and nitrites into nitrAtes. I am hoping the 100 gallon deep sand bed, chaeto filled refugium will keep the nitrates at a decent level. If not, I'll be doing lots & lots of water changes...

mps9506

Well-Known Member

i see i see, ur so smart

I've seen some pretty successful grow out systems with less or more primitive filtration that are very successful. I have a feeling Doni's gonna be extremely successful with this project. I can't wait to see everything develop.

nikkipigtails

Well-Known Member

good work Doni. Can't wait to see it all together.

You would gain a lot of flow by increasing your return pipe to 1-1/2" pipe and then decrease it to 1/2" at each tank. The larger pipe will cause less friction head allowing the pump to function more efficiently thereby delivering more flow. It will lower the water velocity but decreasing the outlets sizes will increase the velocity back up to what it started at.

To actually get almost the same velocity and flow as the pump puts out at the pump exit the friction head must remain low. You obviously can not do anything about static head loss caused by the height you must pump the water though.

There is a simple, easy cheap way to regulate/balance your flow to each tank. At each return to each tank put a female threaded adapter on your pipe. In side each of these female adapters will go a piece of acrylic that you cut with a small hole saw. This would be held in place by a male threaded adapter screwed into the female threaded adapter after inserting the disk. Each disk would have a hole drilled into it. Make disks with different size holes so as to adjust the flow. The further you are from the pump the larger would be the hole in the disk. It is a lot cheaper than using ball valves.

Ideally if you want as close to the rated pumps discharge in the way of flow and velocity at the head height your pumping then the final total interior areas of all your discharge holes must total up to the area of the pumps discharge. I however would not necessarily try for the same velocity but attempt to instead try to get the maximum flow and have it evenly discharged between each tank.

The pump discharge area is Pi x radius^2 or (3.141 x O.5^2) = 0.7854 sq inches. So dividing this by 10 (one for each tank. (0.7854/10) = 0.07854 sq inches for each holes area. This means that the radius of each hole is (area / 3.1416)^0.5 or (0.07854/3.1416)^0.5 = 0.158, this is the radius of the hole diameter needed so the diameter of each hole should average out to be (2 x 0.158) = 0.316 inches in diameter. This means as 5/16 = 0.3125

I would recommend that you consider this as your average size hole and first try using disks with holes this size and see if it gives you balanced enough flow or if you wish to drill some of the holes furthest away a bit larger and use new disks with smaller holes for the tanks nearest the pump. If your return piping is set up in the fashion of a circular manifold fed from both sides I think you would find that holes 5/16" diameter would give you very near matching flow and velocity at each tank.

Disks are readily adjustable just by swapping the for ones with different diameter holes drilled in them. Some people will just use a cap over the pie at each exit and drill a hole in each cap. This second method is a little cheaper, but does not allow for the flexibility that comes from easy swapping of disks.

The drawing below is not pretty, but it shows what I mean about making the return a manifold loop system. Down at the very bottom where there is a little line signifies the pump return feed going to the loop.

To actually get almost the same velocity and flow as the pump puts out at the pump exit the friction head must remain low. You obviously can not do anything about static head loss caused by the height you must pump the water though.

There is a simple, easy cheap way to regulate/balance your flow to each tank. At each return to each tank put a female threaded adapter on your pipe. In side each of these female adapters will go a piece of acrylic that you cut with a small hole saw. This would be held in place by a male threaded adapter screwed into the female threaded adapter after inserting the disk. Each disk would have a hole drilled into it. Make disks with different size holes so as to adjust the flow. The further you are from the pump the larger would be the hole in the disk. It is a lot cheaper than using ball valves.

Ideally if you want as close to the rated pumps discharge in the way of flow and velocity at the head height your pumping then the final total interior areas of all your discharge holes must total up to the area of the pumps discharge. I however would not necessarily try for the same velocity but attempt to instead try to get the maximum flow and have it evenly discharged between each tank.

The pump discharge area is Pi x radius^2 or (3.141 x O.5^2) = 0.7854 sq inches. So dividing this by 10 (one for each tank. (0.7854/10) = 0.07854 sq inches for each holes area. This means that the radius of each hole is (area / 3.1416)^0.5 or (0.07854/3.1416)^0.5 = 0.158, this is the radius of the hole diameter needed so the diameter of each hole should average out to be (2 x 0.158) = 0.316 inches in diameter. This means as 5/16 = 0.3125

I would recommend that you consider this as your average size hole and first try using disks with holes this size and see if it gives you balanced enough flow or if you wish to drill some of the holes furthest away a bit larger and use new disks with smaller holes for the tanks nearest the pump. If your return piping is set up in the fashion of a circular manifold fed from both sides I think you would find that holes 5/16" diameter would give you very near matching flow and velocity at each tank.

Disks are readily adjustable just by swapping the for ones with different diameter holes drilled in them. Some people will just use a cap over the pie at each exit and drill a hole in each cap. This second method is a little cheaper, but does not allow for the flexibility that comes from easy swapping of disks.

The drawing below is not pretty, but it shows what I mean about making the return a manifold loop system. Down at the very bottom where there is a little line signifies the pump return feed going to the loop.

Attachments

LOL Jason

Mike - That means a lot coming from you. Thanks! I just got a confindence boost!

Thanks Nikki

Fatman - thank you for taking the time to write that information and I do understand the concept. That 'disc' method sounds very interesting! I sure would like prevent losing any velocity but I must heed to convenience for this set up. With this growout system, it will be imperative for me to control the water flow and make changes to slowly increase the flow as the fry grow. Also, the ability to turn off flow to one tank at a time is important.

I will consider using a 1.5" return pipe. Thanks again!

Mike - That means a lot coming from you. Thanks! I just got a confindence boost!

Thanks Nikki

Fatman - thank you for taking the time to write that information and I do understand the concept. That 'disc' method sounds very interesting! I sure would like prevent losing any velocity but I must heed to convenience for this set up. With this growout system, it will be imperative for me to control the water flow and make changes to slowly increase the flow as the fry grow. Also, the ability to turn off flow to one tank at a time is important.

I will consider using a 1.5" return pipe. Thanks again!

LOL Jason

Mike - That means a lot coming from you. Thanks! I just got a confindence boost!

Thanks Nikki

Fatman - thank you for taking the time to write that information and I do understand the concept. That 'disc' method sounds very interesting! I sure would like prevent losing any velocity but I must heed to convenience for this set up. With this growout system, it will be imperative for me to control the water flow and make changes to slowly increase the flow as the fry grow. Also, the ability to turn off flow to one tank at a time is important.

I will consider using a 1.5" return pipe. Thanks again!

If your considering using valves there is a lot of fourteen 1/2 inch gate valves on ebay for $25.00 plus shipping. Shipping prices and methods can usually be negotiated as they usually just quote UPS shipping. However even with UPS to Alaska the cost of the gate valves with shipping was still less than for ball valves which are of lesser quality, cause higher flow losses and are not nearly as accurate as gate vavles.

Just search PVC gate valves, they are quite aways down the page under H-018 Lot of 14 1/2" gate valves.