You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

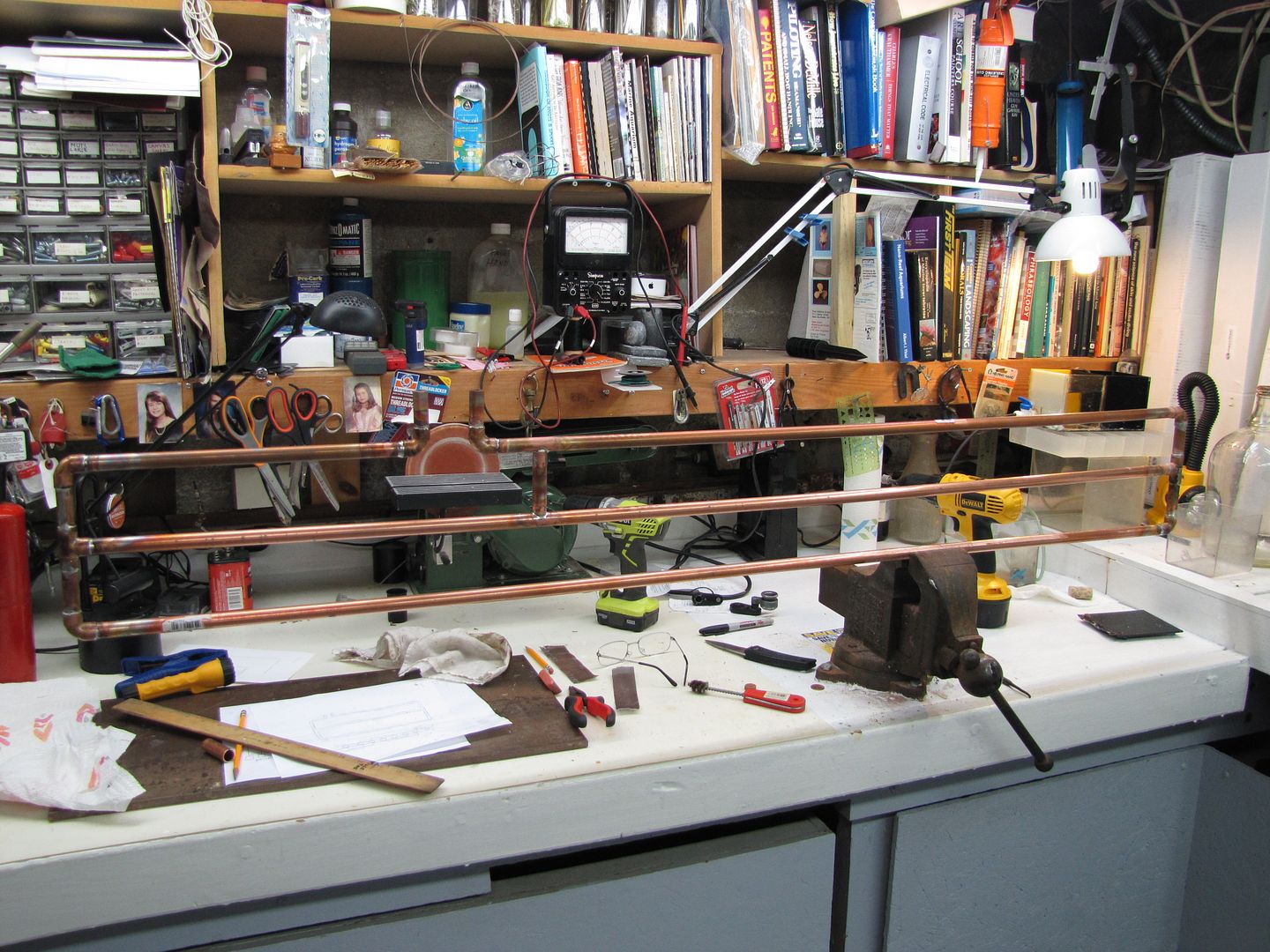

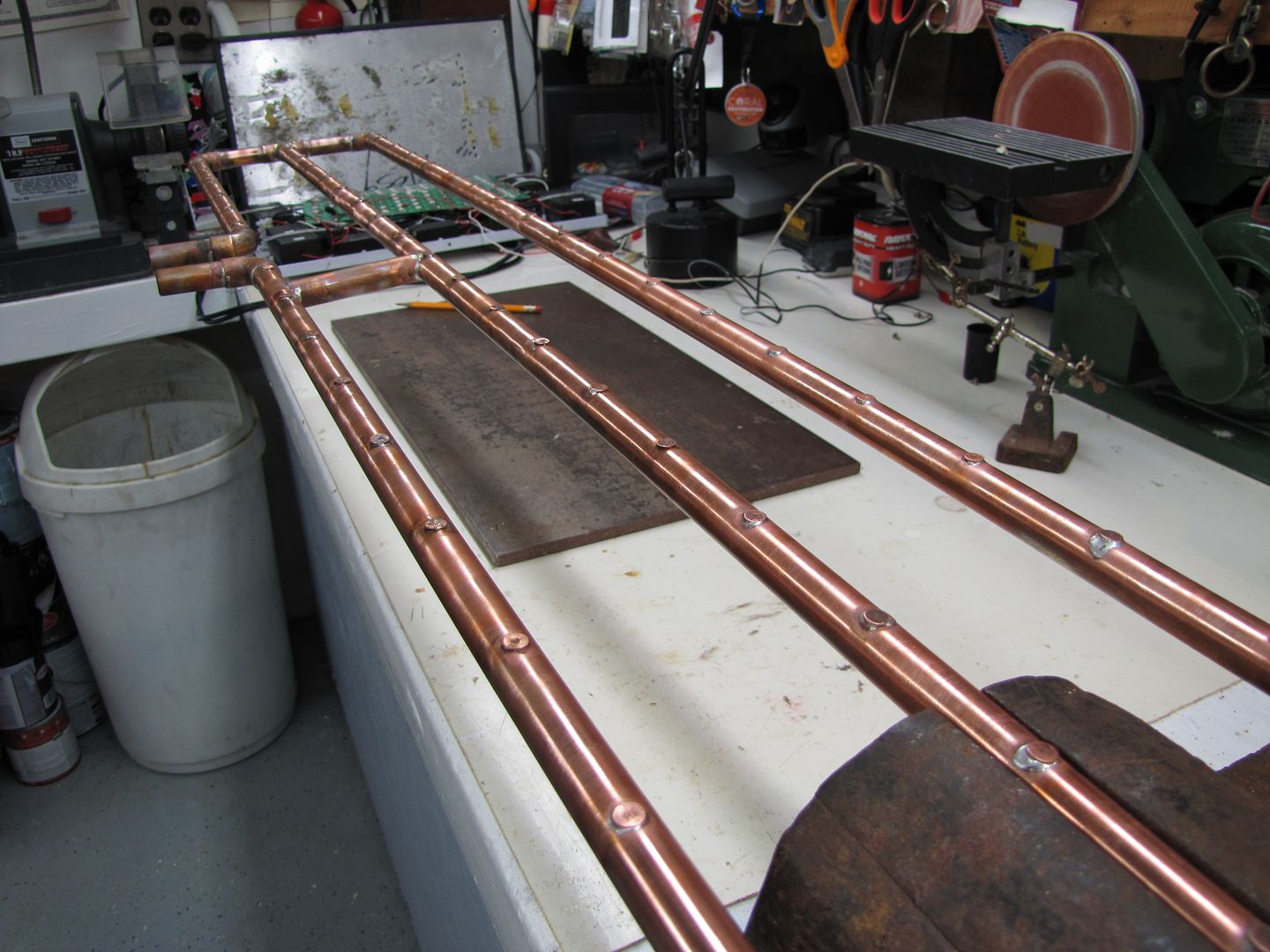

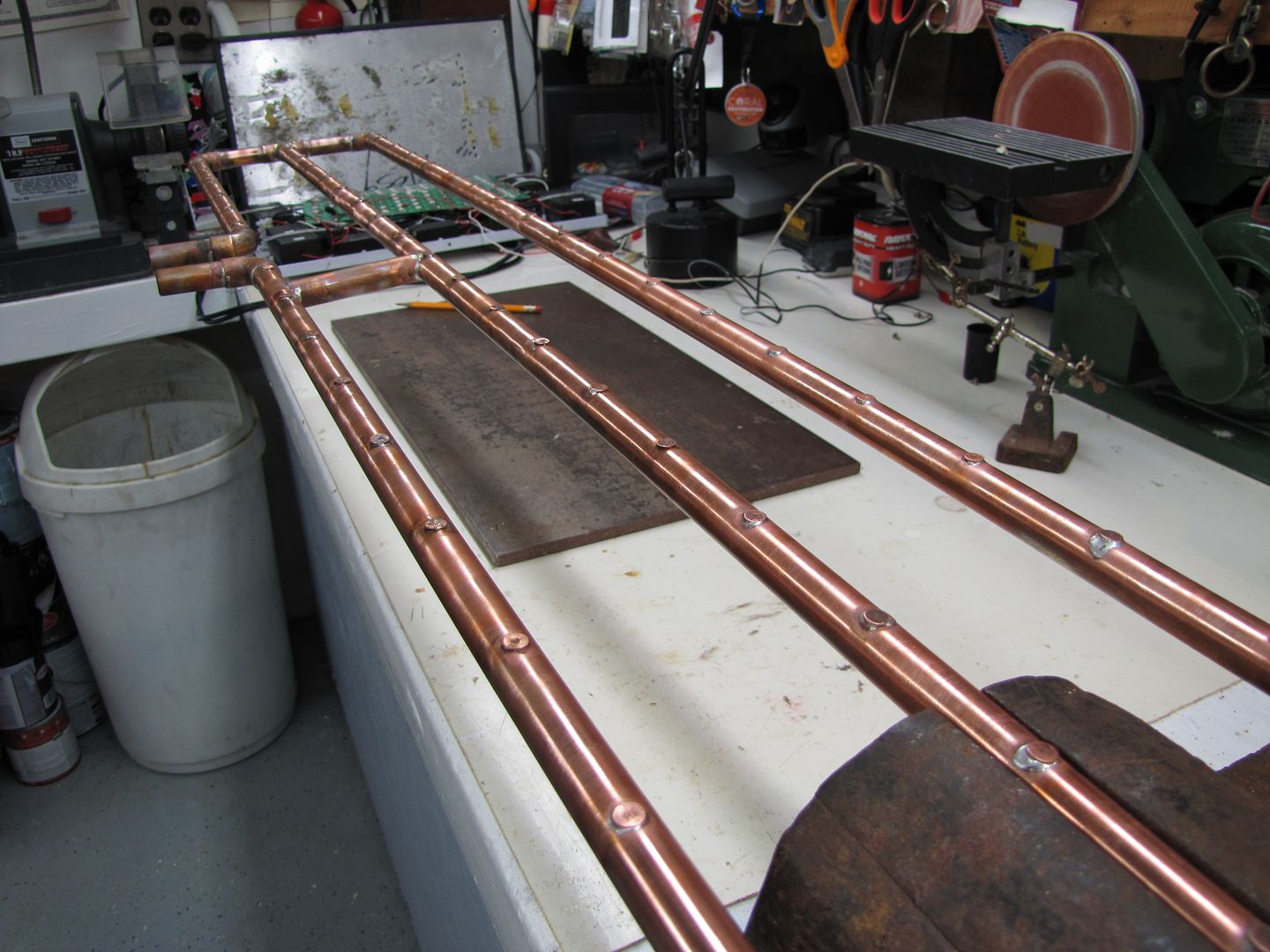

Building a water cooled LED fixture

- Thread starter Paul B

- Start date

This is an interesting project. And I can see how water cooling would allow you to mount a lot of LEDs on a very small area.

I do have one question for you. Don't you worry about the copper pipe around SW? I sure wouldn't want any water on the copper pipe dripping back into the system, and salt water splash does seem to get all over a reef system.

I do have one question for you. Don't you worry about the copper pipe around SW? I sure wouldn't want any water on the copper pipe dripping back into the system, and salt water splash does seem to get all over a reef system.

Paul B

Well-Known Member

Dave, there will be a plexiglass shield under the entire fixture for splashing. I am not worried about the copper. Of course if it falls in the tank, I will have to take up stamp collecting.

I am just doing this as an experiment because I am sure you realize, it is not needed. It's just for fun. And if it don't work, I know where the scrap metal yard it. I just think it is a cool project.

I am just doing this as an experiment because I am sure you realize, it is not needed. It's just for fun. And if it don't work, I know where the scrap metal yard it. I just think it is a cool project.

Squatch XXL

Well-Known Member

What sort of cooler will this be attached to? I used to get into absurd stints of diy, and about 10 years ago I machined (terribly) a copper water block from a bus bar. I used a mag drive pump for circulation through a 89' Chevy Suburban Heater core (no ac). The fan was industrial, and made too much noise....that and CUT headphone wires in 6 places. For a computer, it made too much noise. For a fish tank, it would be quite silent lol.

Paul B

Well-Known Member

I will probably also use a heater core. I wanted to build a radiator from 1/4" copper tubing but it is a pain to get small rigid tubing. I have to drive 30 minutes for it and I don't want to do that. I also have to drive 45 minutes in the opposite direction to get the 6' of plexiglass I want to use as a shield. I have smaller pieces but I would like to make it in one piece. I just came back from Radio Shack to get thermal adhesive and they looked at me like I had two heads. They sell cell phone cases, batteries, robot dogs, MP3 players and headphones but almost nothing in real electronics. That is a shame. As a kid I could go there and get transistors, resistors, motors, solder, tiny light bulbs etc. now unless it is a stupid cell phone accessory, they don't have it so I have to get it on line. It drives me crazy that no one does anything anymore or knows how.

Paul B

Well-Known Member

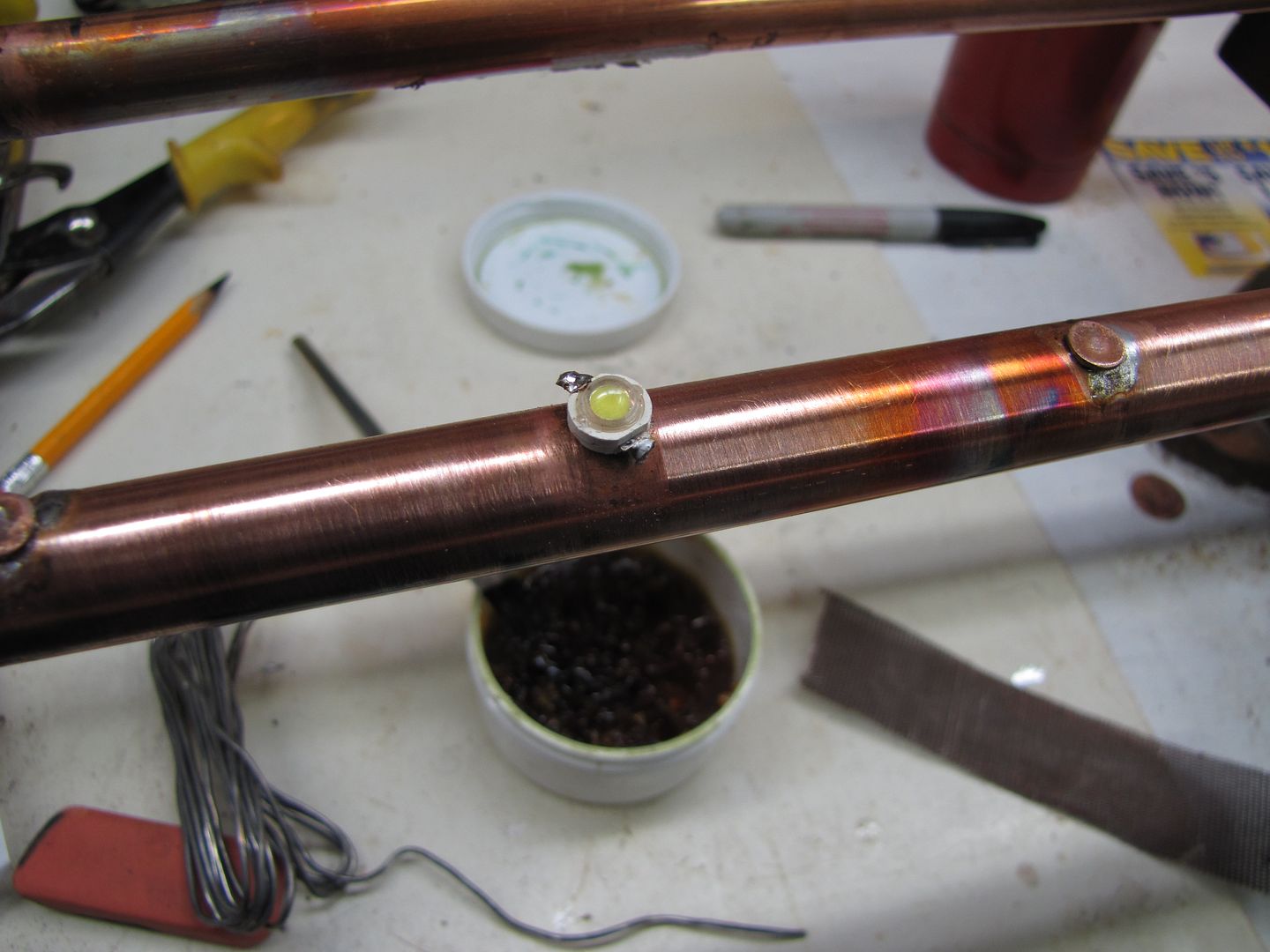

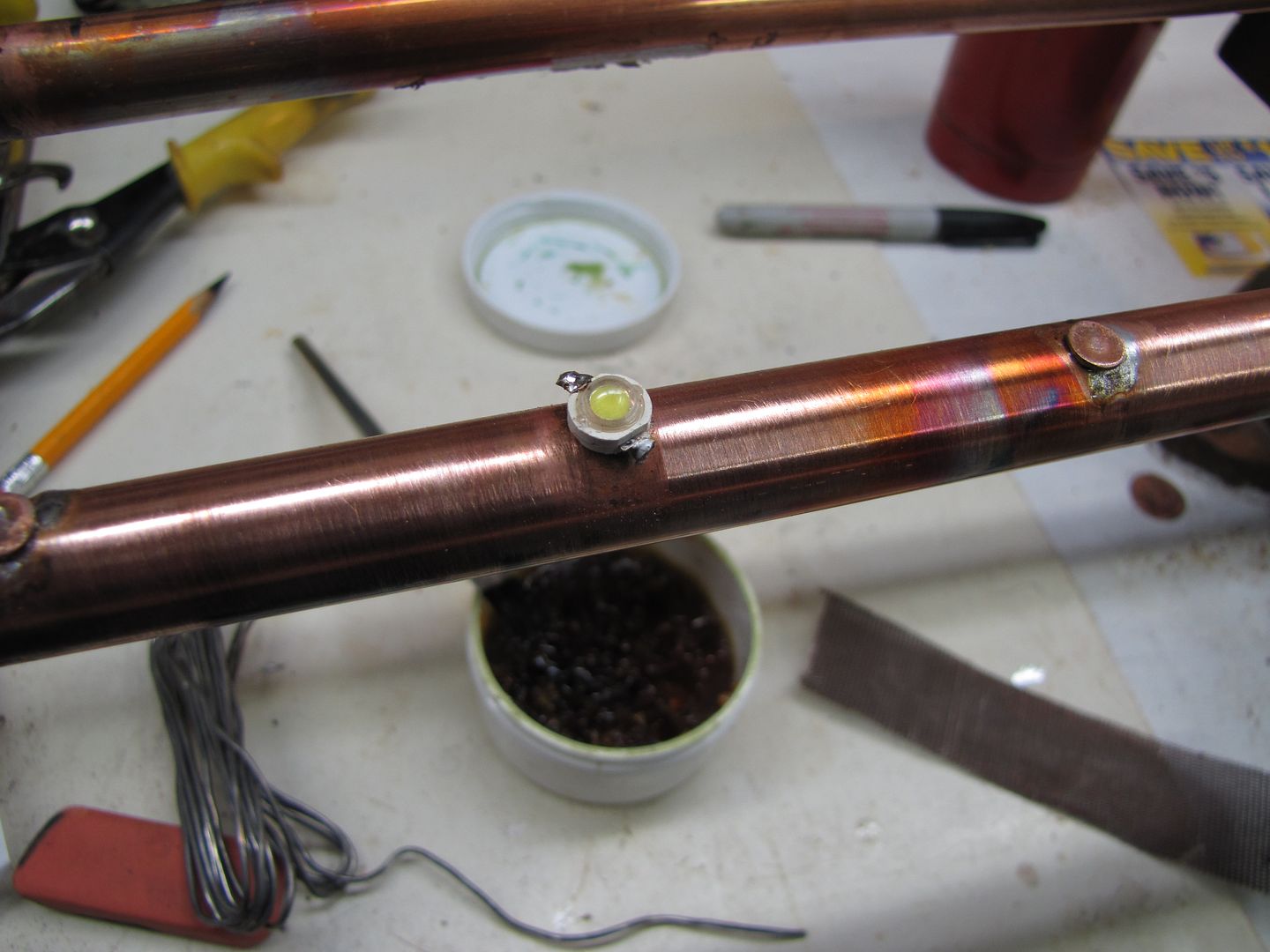

I had to order the thermal adhesive on line because Radio Shack now only sells I Phone cases and little else. So while I am waiting I am making copper disks out of flattened copper pipe and soldering them on to the tubing to give a flat surface for the LEDs.

I used to have a bunch of sheet copper but I can't find it so instead of driving for five minutes to get some, I am using copper pipe and stamping out copper disks with a Whitney Punch. It only takes a few minutes to make 10 of them.

Here are a couple soldered on with an LED laying on it.

I used to have a bunch of sheet copper but I can't find it so instead of driving for five minutes to get some, I am using copper pipe and stamping out copper disks with a Whitney Punch. It only takes a few minutes to make 10 of them.

Here are a couple soldered on with an LED laying on it.

Squatch XXL

Well-Known Member

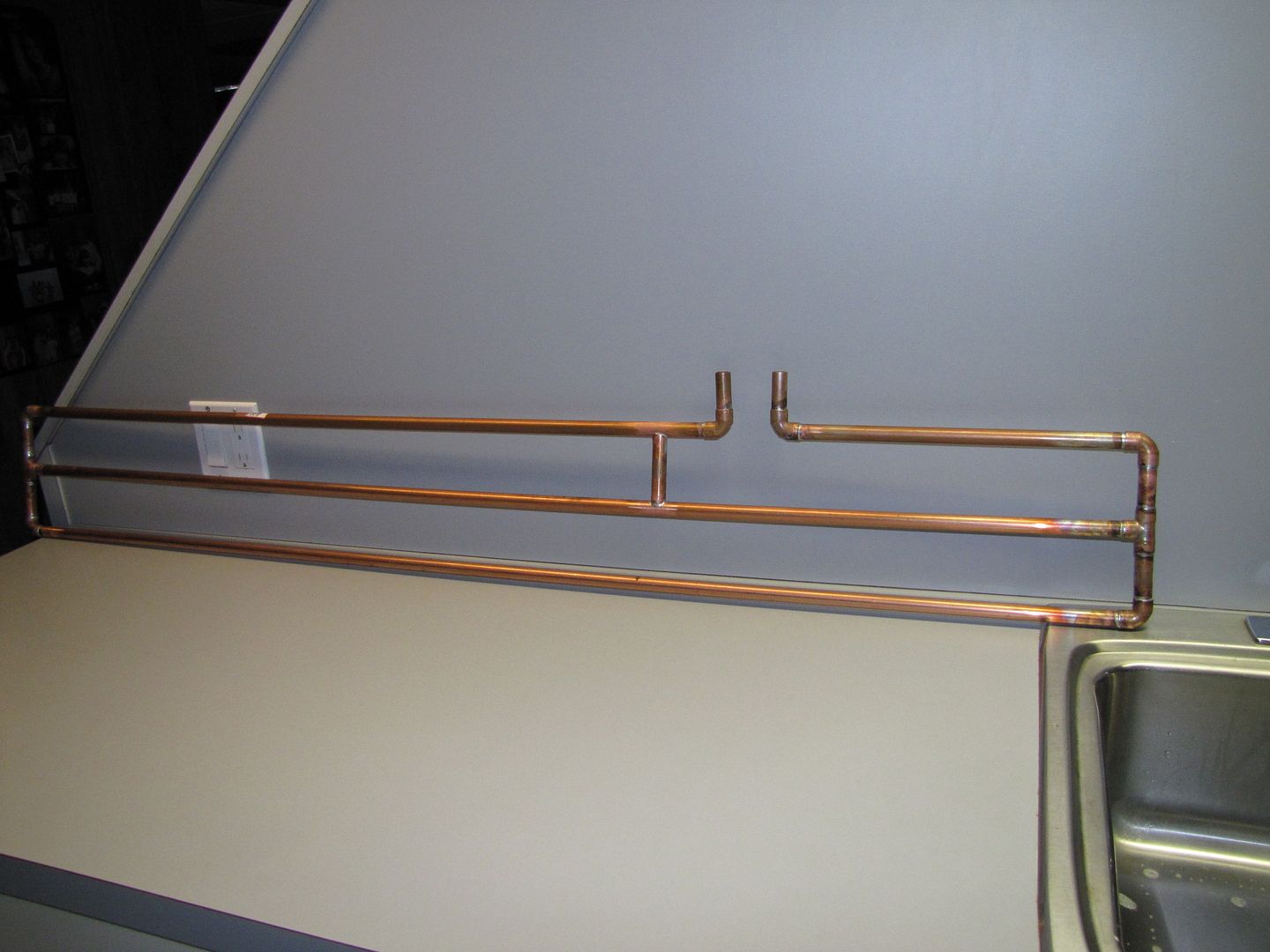

I was looking at your cooler layout. Which end is supply/which is return? Would you need/want any sort of balance valve to push coolant to the further leg?because Radio Shack

Paul B

Well-Known Member

Squatch, thanks but I tested the thing with hot water and all 3 legs get the same amount of water. I also thought I would have to balance it out but it seems to be fine the way it is. Remember, that short piece of pipe is not piped through. It is just a support soldered on to the outside of the pipe. I rounded it off to look better.

Squatch XXL

Well-Known Member

Ahhhhh! I thought it was connected through a pair of tees. Ya that should certainly work a treat! I will continue to watch this develop.It is just a support soldered on to the outside of the pipe. I rounded it off to look better.

StevesLEDs

RS Sponsor

What is the name of that tool that is basically a metal hole punch? I need to get me one!

Jeff

Jeff

StevesLEDs

RS Sponsor

Thanks. Looks awesome, I'm ordering one. http://www.zoro.com/roper-whitney-h...gclid=CMWI6ZXLnckCFYM8aQod4u0KWg&gclsrc=aw.ds

$78.

$78.

Paul B

Well-Known Member

Yep, that's it. Mine is very old and comes in a metal case. They are a very strong, well built tool and not a Girly Man punch. Do you have a lot of holes to punch?

I broke one of the dies in my set and some day I will order it. It is not a tool I use every day but I need it maybe twice a year and when you need it, it really comes in handy

I broke one of the dies in my set and some day I will order it. It is not a tool I use every day but I need it maybe twice a year and when you need it, it really comes in handy

StevesLEDs

RS Sponsor

Well, right now we are using our CNC plasma cutter to make holes, however, sometimes holes are missed, since no machine is perfect 100% of the time. It is a hassle to go back and drill it manually since drill bits migrate in sheet metal. This type of punch would make short work in aluminum sheet.

StirCrayzy

Well-Known Member

Good adaptation of cooling process Paul.

those of us running liquid cooled PCs know how efficient slow moving water and copper can keep things under control.

Glad you chose a splash shield for this one.

those of us running liquid cooled PCs know how efficient slow moving water and copper can keep things under control.

Glad you chose a splash shield for this one.

Paul B

Well-Known Member

Yeah, the absence of a splash shield on my existing light was a mistake.

I punched out and soldered on the 70 copper disks that will support the LEDs. Now (if I get time) I will clean it up more and shoot the entire thing with some clear coat because copper turns green and ugly. This way my Steam Punk look will last. But before I do that, I will make and solder on the supports for the plexiglass shield and also the supports to hang it over the tank. I am waiting for the thermal adhesive. I still have to either build or buy the heater core for the cooling.

I punched out and soldered on the 70 copper disks that will support the LEDs. Now (if I get time) I will clean it up more and shoot the entire thing with some clear coat because copper turns green and ugly. This way my Steam Punk look will last. But before I do that, I will make and solder on the supports for the plexiglass shield and also the supports to hang it over the tank. I am waiting for the thermal adhesive. I still have to either build or buy the heater core for the cooling.

Squatch XXL

Well-Known Member

I don't know how "DIY" you want this to look, and I don't know your total thermal needs.....But I would tell you that IF you can pick up any automotive radiator, you should be able to get away with 100% passive cooling. A heater core would require a fan for sure if everything I read about LEDs and heat is true.I still have to either build or buy the heater core for the cooling.

For what you can snag a used heater core from the web, it is preposterous to build one. I have had a few water cooled custom pc (I did all the diy on them) over the years, and each had a different heater core to fit where I wanted it to look and be the coolest. I never paid more than $30 and they beat the snot out of products specifically for the pc...it just required some DIY fittings and some solder.

Paul B

Well-Known Member

I have quite a few auto junk yards here so a heater core will be easy. I probably already have the fan. I think I may have 10 fans. Adapting it to work on this system will be easy.

I would rather build the radiator but it is not easy getting 1/4" rigid copper tubing and I don't want to use flexable tubing

I would rather build the radiator but it is not easy getting 1/4" rigid copper tubing and I don't want to use flexable tubing