cracker

Well-Known Member

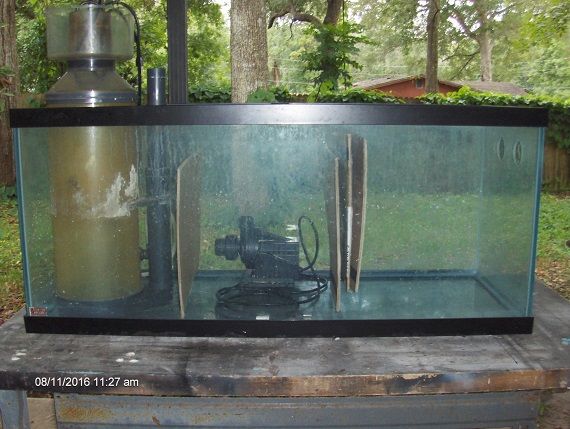

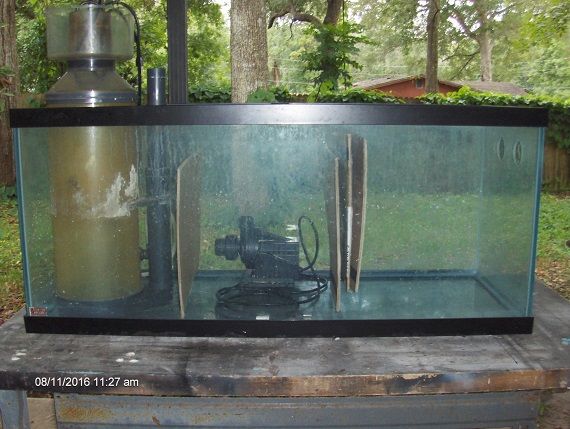

So I got some cardboard today I think I have enough room.

I have just a wall between the skimmer and return section. I'll be using a herbie /bean type overflow so expect very little bubbles. If I can get away with just a wall between the ref and return that's a couple more inches. I'm concerned about debris(chaeto) getting into the return section. maybe some type of screen. After all I can't see a 3 panel baffle keeping debris out of the return section anyway. If I keep the drop from the ref to return I can avoid many bubbles. Think it's doable ?

So I have 15 inches for the skim section return 14 and refugium 15 "or 16 " depending on baffles. Thes are close but still rough dimensions.

I have just a wall between the skimmer and return section. I'll be using a herbie /bean type overflow so expect very little bubbles. If I can get away with just a wall between the ref and return that's a couple more inches. I'm concerned about debris(chaeto) getting into the return section. maybe some type of screen. After all I can't see a 3 panel baffle keeping debris out of the return section anyway. If I keep the drop from the ref to return I can avoid many bubbles. Think it's doable ?

So I have 15 inches for the skim section return 14 and refugium 15 "or 16 " depending on baffles. Thes are close but still rough dimensions.