StirCrayzy

Well-Known Member

I've had this unit since 2007 and bought because it was the cheapest RODI unit I could find at the time. I have good water pressure, and 110 ish TDS coming out of the faucet, and have never been dissapointed with the performance of this product. It has never failed to deliver 0 TDS output when maintained.

I don't think I've ever really had any failures other than a phantom drip from the bottom of one canister. It uses all of the standard 10" filter cartridges and bulk DI resin ( since buying the refillable cartridge) , and can accept higher rates membranes.

So, two circumstances collided to finally make a substantial change.

1. All filters are due for replacement. I do this once a year, for carbon and sediment, DI whenever it's needed, but I can't remember if I've ever changed the membrane itself... I know, should've scribbled it on the housing or something. I've also never flushed the membrane intentionally. At best I might have replaced this in 2011 ... ?

2. My tank is not in the greatest condition suddenly, and I'm checking things off the list of possibilities.

I'm not sure if this is the membrane that came with my PureFlo2 or if it's a replacement, but lists at 60 gpd which is close to what I have been producing , under 50 gpd.

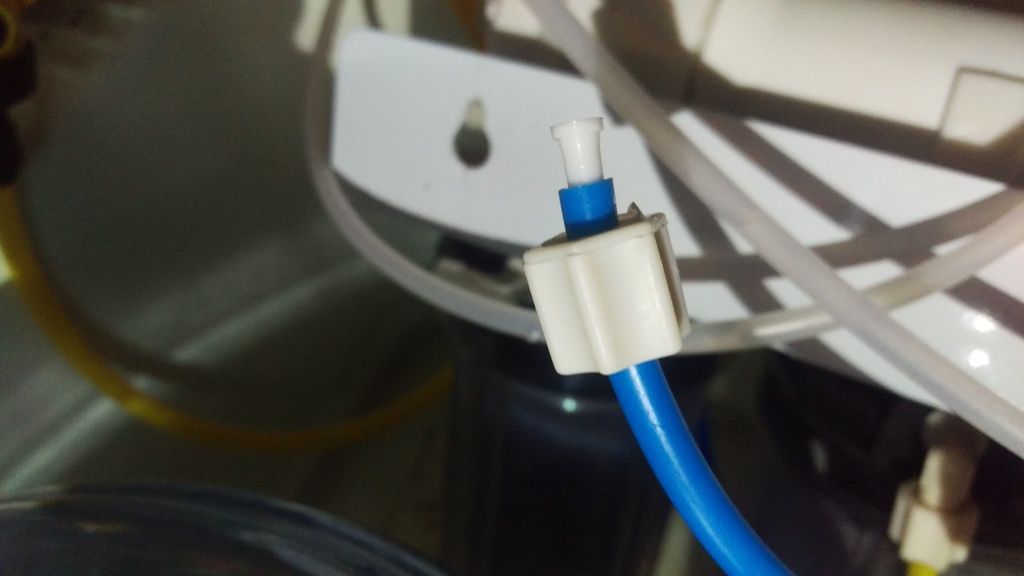

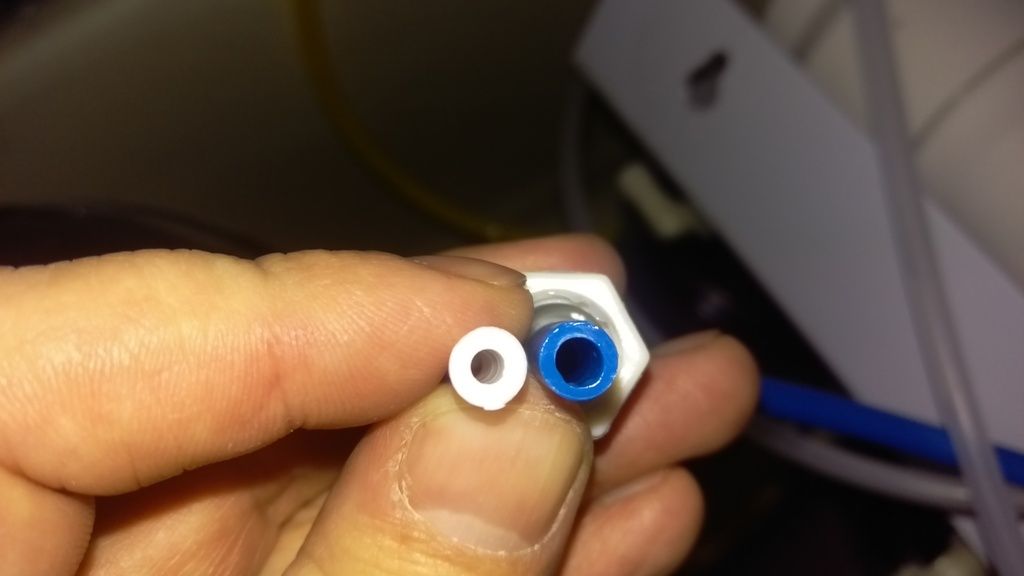

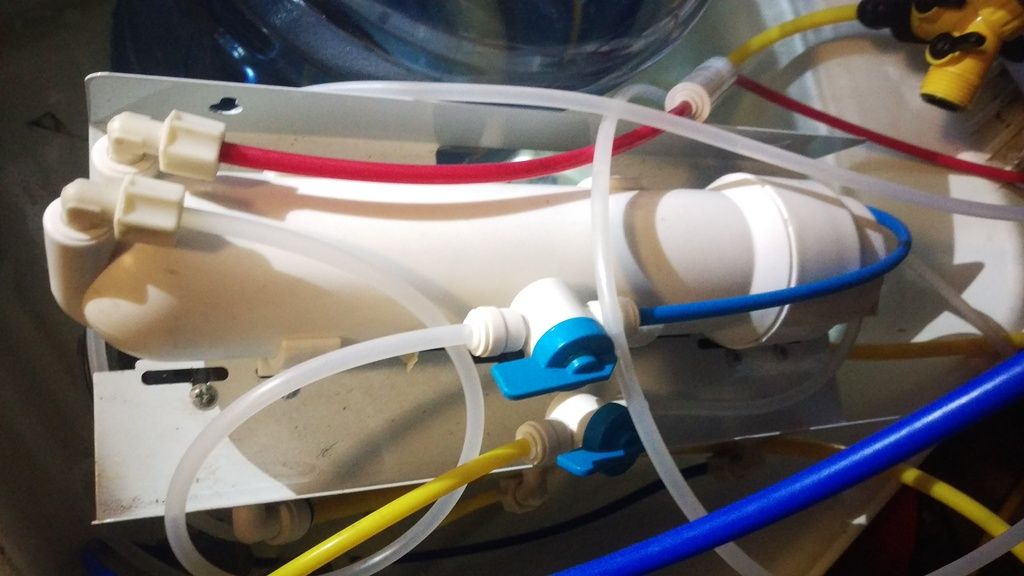

Disassembled....

I ordered a full round of filters which arrived yesterday, including a DOW film-Tech 75 gpd membrane and flow restrictor from BRS.

After reassembly, the frustration began with getting 1:1 waste to product ratio. Then trying to find the flow restrictors...I now have 4:1 ratio.I'll test again Tonite, I'm not sure if I'm getting full production yet.

More to follow later...

I don't think I've ever really had any failures other than a phantom drip from the bottom of one canister. It uses all of the standard 10" filter cartridges and bulk DI resin ( since buying the refillable cartridge) , and can accept higher rates membranes.

So, two circumstances collided to finally make a substantial change.

1. All filters are due for replacement. I do this once a year, for carbon and sediment, DI whenever it's needed, but I can't remember if I've ever changed the membrane itself... I know, should've scribbled it on the housing or something. I've also never flushed the membrane intentionally. At best I might have replaced this in 2011 ... ?

2. My tank is not in the greatest condition suddenly, and I'm checking things off the list of possibilities.

I'm not sure if this is the membrane that came with my PureFlo2 or if it's a replacement, but lists at 60 gpd which is close to what I have been producing , under 50 gpd.

Disassembled....

I ordered a full round of filters which arrived yesterday, including a DOW film-Tech 75 gpd membrane and flow restrictor from BRS.

After reassembly, the frustration began with getting 1:1 waste to product ratio. Then trying to find the flow restrictors...I now have 4:1 ratio.I'll test again Tonite, I'm not sure if I'm getting full production yet.

More to follow later...